Storing water makes little sense

What makes fruit juices special are the vitamins, minerals, fruit acids, fruit sugars and flavours. However, these essential substances only make up a small proportion of the juice. The rest is ordinary water, up to 90%. How do you separate the nutritious substances from the water? Technicians all over the world had been working on a process to do just this since the 1920s. It had the potential to massively reduce the effort required for storage and transport. The first fully developed systems came onto the market in the 1950s. The principle is simple: The juice is gently heated under vacuum. The water evaporates at temperatures that make little difference to the other substances.

The Rauchs were particularly interested in this technology. Since the 1930s, they had been preserving their fruit juices by adding carbonic acid using the Seitz-Böhi process. This ensured the best juice, but required expensive pressure tanks for storage. "In 1957 we tried it out with a partner company in Switzerland," remembers Erich Rauch. "In the morning we loaded 18 barrels of fresh, clarified apple juice onto a truck.

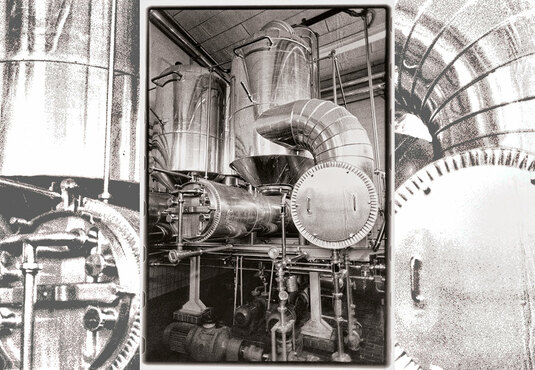

In the evening we unloaded 1 1/2 barrels of concentrate." In 1958 Rauch installed the first concentrate plant of its own in Rankweil - a small downdraft evaporator with a capacity of 1,200 l/h. The steam for this aroma plant was supplied by the boiler of an old locomotive. It had previously transported passengers from Salzburg to Bad Ischl and back for decades. Maybe even the Emperor.

The boiler of a decommissioned locomotive from the Bad Ischler railway supplied the steam for the first Rauch concentrate plant.